Why choose Vallo Sheet Metal Machining?

1. Sheet metal parts achieve both lightness and strength through bending, reinforcing ribs, welding and other processes;

2. Different structures, sizes and thicknesses can be flexibly adjusted.

3. Cutting, stamping, bending, welding, assembly, spraying, silk-screening, etc. can be integrated to greatly reduce assembly costs and time.

4. The surface of sheet metal parts can be sprayed, electroplated, brushed, anodized and other treatments to improve protection and aesthetics to meet different product positioning.

Vallo Sheet metal is widely used in mechanical equipment, electronic appliances, automotive industry, communication equipment, medical equipment, smart terminal shells and other fields.

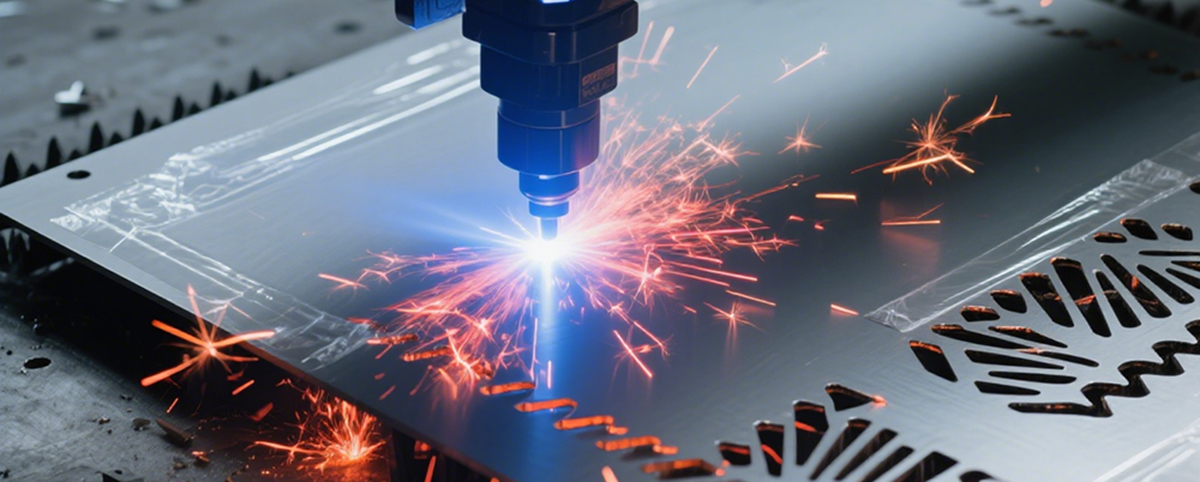

Use fiber laser cutting machine, fast cutting speed and neat edge

Can cut carbon steel, stainless steel, aluminum alloy, etc.

High-speed stamping machine cooperates with mold to process holes, bumps, louvers, and reinforcement ribs

CNC bending machine (more than 4 axes) can achieve multi-angle composite bending

Applicable to stainless steel, aluminum, carbon steel and other materials;

Vallo experienced welder team ensures neat, firm and beautiful welds

Applicable to stainless steel, aluminum, carbon steel and other materials;

Vallo experienced welder team ensures neat, firm and beautiful welds

Nut riveting, stud welding, structural assembly

Structural strength test, electrical ground resistance test, etc. (optional)

Vallo Sheet Metal machining service are widely used in multiple industries

Automation equipment racks, chassis, electric control cabinets, sensor brackets

Communication equipment 5G cabinets, base station housings, antenna covers

New energy industry photovoltaic brackets, battery boxes, electric control devices

Medical equipment medical housings, detector housings, stainless steel support components

Home appliance industry air conditioning frames, electric heater chassis, oven liner

Smart security camera housings, monitoring boxes, access control equipment panels

Industrial control cabinet door panels, operation panels, signal boxes, power supply housings