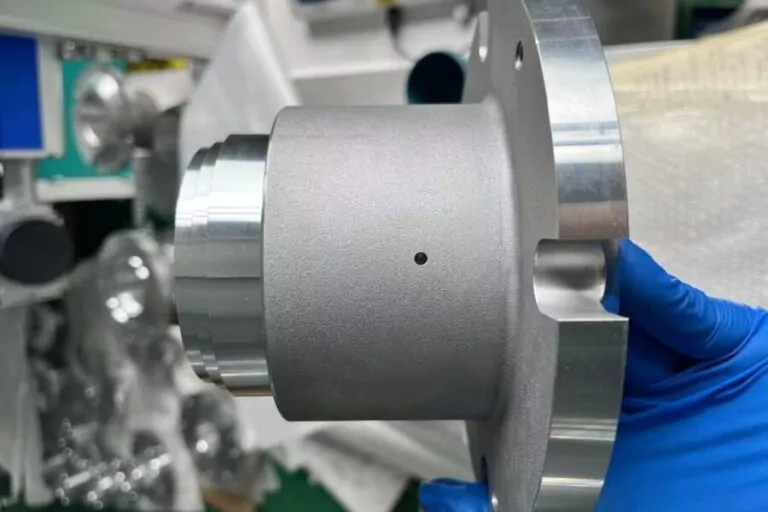

Materials: Aluminum alloy, Stainless Steel, Brass, Copper, Plastic (POM, ABS, PEEK, etc.)

Equipment: CNC lathe, CNC milling machines

Application: used in aerospace, medical equipment, automotive precision parts, automation equipment and other industries

Processing:

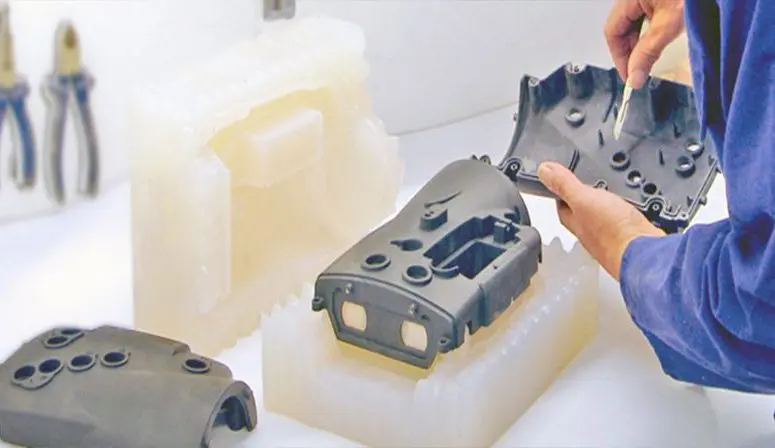

SLA: High precision, for appearance verification and display samples;

SLS: Suitable for industrial strength parts;

Material: Resin, Nylon, ABS, Stainless Steel, Aluminum alloy, etc.

Applicable: Structural verification, functional samples, product development stage

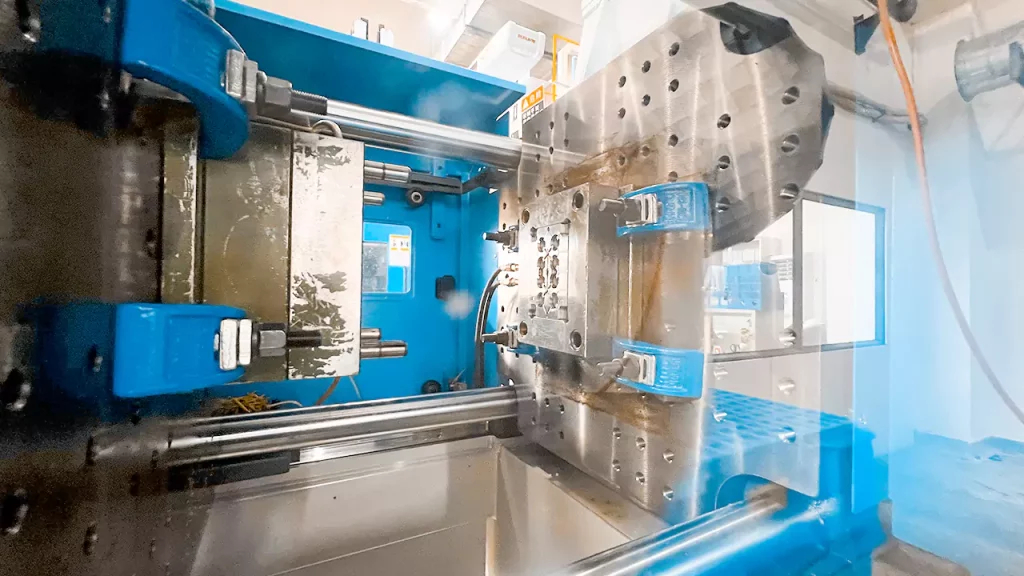

Materials: ABS, PC, PP, PA, POM, TPU, TPE,etc.

Advantages: Smooth surface, Complex structure, High efficiency, support for two-color/rubber molding

Typical products: Electronic housings, home appliance parts, medical accessories, automotive interior parts, etc.

Processing: Master model manufacturing (usually using SLA 3D printing) → Silicone mold → Vacuum injection → Finished product curing

Materials: PU resin, Soft rubber, Transparent material, etc.

Application: Appearance samples, functional test pieces, market verification pieces, small batch production pieces, etc.

Materials: Cold-rolled Steel plate, Stainless Steel, Aluminum plate, Copper plate, etc.

Processing: Laser cutting, Punching, Bending, Welding, etc.

Features: Low cost, flexible batch size, strong structural stability

Molding advantages:

- Excellent dimensional accuracy and surface quality

- Suitable for complex thin-walled structural parts

- High strength, suitable for structural load-bearing parts

Application: Automotive parts, LED radiators, Industrial connectors, Motor housings, etc.